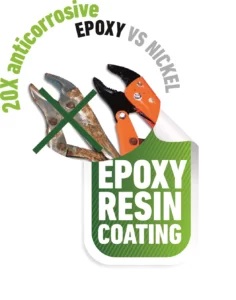

Epoxy resin is 20 times more corrosion-resistant than nickel pliers

PIONEER and UNIQUE Manufacturer in the World

The spreading of rust is much quicker below nickel-plated surfaces than epoxy-painted surfaces.

Using epoxy resin in the manufacture of our locking tools is far more environmentally friendly than nickel or chrome. This is in line with the prestigious ISO 14000 which instigates, among other things, the use of non-polluting agents.Corrosion Nickel Tool Epoxy Top Gripon

An epoxy-painted finish provides greater electrical insulation than nickel or chrome plating allowing greater resistance to welding pellets.

The qualities of epoxy resin ensure a better coating in concealed or inner areas. I.e. the “Faraday effect” is minimized compared to nickel or chrome plating.

A color-painted finish is more visible in the workplace. This reduces the incidence of loss and can reduce the risk of injury.

Unique user of EPOXY resin on Locking Pliers & C-Clamps manufacturing.

Wholest Locking Pliers and Steel Clamps range

ViseBrench of Hands-Free Concept for Locking Pliers and Clamps

High Jaws, clamping capacity

Pliers & Clamps from 5″ to 40″ size.

Using epoxy paint helps distinguish the tools on the marketplace and allows for a customized finish by using corporate colors.

Nickel vs. Epoxy

Grip-on manufactures the widest and most modern range of locking pliers & clamps worldwide.

Continually producing top quality and innovative tools to meet the growing demand of Welding, Metal Work, Maintenance, Pipe, Auto Mechanics, Auto Body, DIY, Woodwork, Retail and Multi-use.